FEEDING PIGS IN EXTENSIVE PRODUCTION

By: Dale W. Rozeboom, Michigan State University

Introduction

Extensive pork production[1] is often driven by the objectives of a market niche, what may be easiest to do when beginning to farm, and what generates some profit, rather than what is most efficient and costs the least. Extensive farmers may be willing to accept biologically inefficient production methods and more costly inputs compared to commodity producers, and consequently seek markets willing to compensate them for the unique product they produce. Their farms are not large enough to take advantage of economies of scale.

Like in the mid-20th century, today’s extensive pork producers are raising pigs outdoors or in low-cost buildings. Initially, they manage feeds and feeding in those settings. New farmers are excited and may be willing to spend extra money if needed for the principles and beliefs they adhere to. They successfully sell to like-minded consumers. The excitement begins to wear off if customers stop buying because products are too expensive. If this happens, the new farmer must find ways to reduce costs or find customers willing to pay more in order for the farm business to be profitable. They must ask how they can decrease cost of production, and search for the most valuable change they can make to their current feed procurement plan; realizing that feed is the most expensive input.

In this bulletin, several management and procurement approaches are discussed relative to feeding pigs in extensive settings. Feed is available in ready-to-feed bags, ready-to-feed bulk, or growers can purchase ingredients and formulate their own. The cost of feed decreases with increasing responsibility for grinding, formulating, mixing, storage and quality control. Taking on responsibility for devising the nutritional program and making the feed must result in equivalent or improved production and a cost improvement that accounts for the added time and knowledge (more time formulating, buying individual ingredients, more automation for bulk procurement of ingredients, equipment and power to manufacture feed, automation for delivery to bins, and delivery to feeders).

Meet Nutritional Requirements

Desirable growth, animal health and product quality are most readily obtained by providing pigs their daily nutrient requirements, each day. Feed ingredients are included to provide nutrients in one of four major categories: energy (often grains, cereals or high quality forages), amino acids/protein (often soybean meal, or animal products), vitamins/minerals (often diet is balanced by adding a specific pre-mix of these) and water (fresh and clean unlimited). We think of growing pigs needing more protein to support muscle growth, with protein levels decreasing as the pig grows. Breeding animals normally are limit fed to prevent them becoming too fat, but once they farrow ad libitum feeding is best to support milk production.

Daily rations should be specific to the stage of growth and (or) reproduction, and they should provide minimum daily requirements suggested by the National Research Council (NRC)[2]. Understand that NRC guidelines are aimed at the majority of pigs, more of which are higher lean growth than most heritage breed pigs, and more often raised indoors. Because extensively reared pigs are typically outdoors for part each day, the requirements of NRC, which are minimum requirements, are sufficient because feed intakes are generally greater in extensive/outdoor situations. Further discussion about the basics of nutrition, ration formulation, intake allowances, and the contribution of grazing may be found Swine Nutrition[3] and the National Swine Nutrition Guide[4], and a review about feeding swine in niche situations by Dr. Allen Harper (2012)[5].

Buying Complete Feed

Feed that is ready to be fed to pigs is referred to as a ‘complete feed’, as it contains all required nutrients. The ingredients may be grains, grain by-products, forages, dried animal products, minerals, and vitamins. These complete feeds are made at a feed manufacturing facility, which is sometimes a local grain elevator and sometimes a regional commercial feed mill. Complete feeds may be purchased from the local elevator, farm stores, or from an area feed dealer. Local elevators will provide feed in bulk or bagged. Feed from farm stores or dealers is typically in bags and referred to as ‘floor stock’. The potency of vitamins and minerals in a complete feed decreases with time, exposure to heat and moisture, and sunlight if in clear plastic. This is referred to as ‘shelf-life’, and the sellers and buyers of complete feed share responsibility for the quality of feed presented to the pigs. When you purchase a complete feed, you are buying their expertise in knowing the dietary requirements, nutrient availability in the feedstuffs used in the mix, grinding and mixing, and quality control. With the purchase of the complete feed, you do not grow or buy the feed ingredients. You do not have to store feed ingredients and be concerned about loss of nutrition, pest infestation, and spoilage.

The complete feed made by small local grain elevators is typically in meal form. Larger commercial feed mills often make feeds in pellet form. Pelleted feed is more expensive. The first advantage of pelleted feed is that pigs cannot sort through their feed, so each bite represents the balanced diet as designed. The second advantage of pelleted feed is that the pigs waste less feed and the feed-to-gain ratio is more desirable. With a well-designed feeder, more frequent small meals, and less feed wastage, the feed-to-gain ratio of pigs receiving feed in meal form can be equal to those received pelleted feed. Taking measures to minimize feed waste, regardless of feed form, may have far greater economic payback than changing your procurement approach from buying complete feed to some degree of at-home mixing. If you see feed on the ground around a feeder you know you are wasting over 10%.

Shop for Best Feed Price

One day in December of 2014, three elevators and one local farmer (with 6000 sows and an on-farm mill) were asked the cost of one ton of a 15% crude protein finishing ration. The answers received were $251, $320, $256, and $141 per ton. Take time to call or visit elevators in your vicinity to shop for a less expensive price. Investigate if it is possible to negotiate feed price based on a larger quantity and a commitment to buy for an extended period of time. When buying from a mill or elevator that you have not used before, ask other customers how their pigs have performed on the ration you are considering.

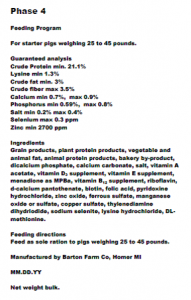

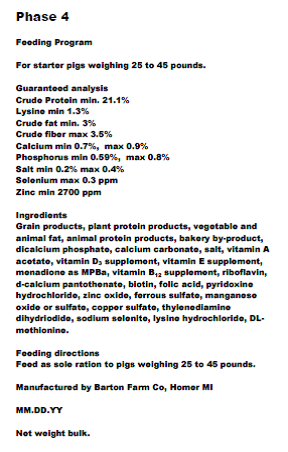

Do your best to evaluate nutritional equivalency when shopping by comparing feed tags. All commercially available feeds must be labeled, and that label must include a guaranteed analysis stating the nutrient concentrations guaranteed by the manufacturer[6]. Concentrations of all trace minerals (copper, zinc, iron, selenium, manganese, and iodine) and vitamins (A, D3, E, K, B12, riboflavin, pantothenic acid, niacin, choline, biotin, folic acid, and pyridoxine) may not be presented on the feed tag, but they are important and rations must be balanced for them. The feed tag must also include the common name of each ingredient. Some states permit use of ‘collective terms’ for ingredients of similar type (common origin and similar function). This allows the manufacturer to substitute one ingredient for another as market prices fluctuate. In contrast, some feed manufacturers use a locked formula where feed products are made using the same ingredients time after time. Feed milled according to a locked formula may fluctuate more in price with ingredient availability. Additional information needs to be included on the label (Figure 1) if a medication has been added to the feed.

[1] The descriptive term used here is ‘extensive’ and represents the niche, small farm, back-yard, local, heritage, out-back, and (or) part-time producers who want to do it themselves, on their own property. Typically, the numbers of growing and reproducing pigs are 3-100.

[2] NRC. 2012. Nutrient Requirements of Swine. 11th rev. ed. Natl. Acad. Press, Washington, DC.

[3] Swine Nutrition, Second Edition, Ed’s Austin J. Lewis and L. Lee Southern, CRC Press 2000. Print ISBN: 978-0-8493-0696-9. eBook ISBN: 978-1-4200-4184-2.

[4] National Swine Nutrition Guide. 2010. U.S. Pork Center of Excellence. 1202 NSRIC, Iowa State Univ., Ames IA 50011.

[5] Harper, A. F. 2012. Feed and feeding options for small-scale and niche market pork production. Proc. Small-Scale and Niche Market Pork Production Conf. Tidewater Agricultural Research and Extension Center (TAREC), Suffolk, VA, October 26 – 27, 2012. Available at: http://www.arec.vaes.vt.edu/tidewater/files/proceedings-pork-production.pdf.

[6] Nutrients which must be guaranteed are determined by each state’s government agricultural agency.

Figure 1. Example of the information found on a feed tag

Bulk or Bagged

Feed bins, wood, metal or plastic, allow for the storage of ‘tons’ of feed. The price benefit of buying complete feed in bulk may be significant. The cost advantage may pay for a used or new bin in a few years if the number of pigs you feed annually is large enough. The price difference between bulk and bagged complete feed will be specific to the feed mill and the distance from the mill to your home. The price advantage with purchasing bulk feed is obtained with quantities of one ton or more. Many local elevators cannot make smaller quantities easily and accurately. Most mixers are not made to uniformly mix 500 pound batches, and the charge to make a batch of less than one ton has either the same “mix” cost as one ton, or may even be greater. Building your own bins from wood may be cheapest. Wood, however, is very difficult to sanitize if that becomes necessary following exposure to a pathogen, mold, mycotoxin or other anti-nutritional factor.

For an example, let’s say that the price of bagging is $15 per ton, and the price of a new galvanized steel bin is $1250, the purchase of about 84 tons of feed in bulk instead of bags would pay for the bin. The cost of the bin may be spread over several years, making the prospect of payback achievable with even fewer pigs. Thus, the factor in making a decision to purchase a bulk feed bin, is having enough pigs to consume at least a ton of a specific diet. North Carolina State University in their Swine Nutrition Guide[1] states that a sow and her 18.5 pigs will consume 7.3 tons of feed annually in a distribution (column heading “% of total”) as shown in Table 1. The right-hand column shows the estimated number of animals (pigs or sows) that need to be in a cohort to consume one ton of feed. So it takes at least 254 nursery pigs to consume one ton of their first diet and it takes at least 5 nursing sows to consume a ton of lactation feed. Likewise, only 20 feeder pigs will justify the purchase of bulk feed for rearing to harvest weights.

[1] Swine Nutrition Guide. Feed processing. North Carolina State University, Available at: http://www.cals.ncsu.edu/an_sci/extension/swine/nutrition/nutritionguide/default.htm.

| Table 1. Feed usage by stage of production. | |||

| Diet | Typical weight, lbs. | % of total | Number of animals to consume one ton of feed |

| Starter 1 | 12-15 | 1 | 254 |

| Starter 2 | 15-25 | 2 | 127 |

| Starter 3 | 25-50 | 3 | 85 |

| Grower 1 | 50-125 | 13 | 20 |

| Grower 2 | 125-200 | 20 | 13 |

| Finisher | 200-mkt | 45 | 6 |

| Gestation | 350-500 | 10 | 3 |

| Lactation | 350-500 | 6 | 5 |

If one ton of feed is too much for the number of pigs you plan to feed, then various consequences need to be considered. With too few pigs being fed in a given growth period on the small farm, then you may feed them a diet longer, which is over-fortified for them. Or you may feed an under-fortified diet early, as it is cheaper. Underfed pigs grow more slowly and deposit less lean mass, particularly when 2 to 4 months of age. This results in less product, and the butcher or customer saying that the hogs are “too fat and there is not enough ham.” Overfeeding is a waste of money and a greater environmental responsibility as excess nutrients are excreted. If one ton of feed is too much, consider whether it may be possible to split orders with other farms in close proximity. Many small farms will need to purchase starter feed in bags, but may be able to take advantage of bulk pricing for feed for market hogs or sows.

Mixing Complete Feeds

If one ton of feed is too much, you may consider planning ahead for the mixing of two different complete feeds. This can be advantageous as it still allows you to purchase feeds in one-ton quantities which is less expensive than buying smaller quantities. Mixing two complete diets together eliminates the over-feeding of nutrients as pigs get older and the under feeding of pigs in cases where the price of feed encourages the avoidance of purchasing too much of the expensive starter diet. Mix proportions of a “dense” ration with a “less dense” ration to get a “moderately dense” ration. For example, a grower 1 diet containing 1.1% total lysine could be mixed 1-to-1 with a finisher diet containing 0.8% lysine, and the resulting feed would be 0.95% lysine and appropriate as a grower 2 diet. This simple example assumes that other amino acid concentrations will be portioned similarly and that the minerals and vitamins in both the grower 1 and finisher diets are equal. If not similar, then the ‘mixed diet’ should be evaluated for any estimated concentrations that do not meet the minimum of NRC guidelines (2012)2. You can blend by the scoop, bucket or bushel basket full. You use the feed quickly and avoid loss of available nutrients with extended storage. You do not have to store feed until the next reproductive cycle, when you have pigs of a given maturity once again. And you do not have to own a grinder-mixer.

Topdressing

Purchasing one ton of bulk complete feed may still be an option, even if you do not have enough pigs to eat all of it in an appropriate amount of time. With topdressing, one ton of a “less dense” ration is purchased, and then daily portions are top-dressed with soybean meal or another protein source with each feeding. You may buy one bag of soybean meal at a time. The amount of soybean meal will vary and decrease as pigs grow; anywhere from a quarter to one full cup (about 150 grams) per pig per day. One cup of 47.5% soybean meal provides about 4.7 g of lysine. The farmer who grows soybeans or other protein sources can use these to topdress, keeping in mind that soybeans must be cooked or steamed prior to feeding.

Grind and Mixing Feed at Home

A farmer may grind and mix their own rations if they have accurately determined that the cost savings in doing so are real. The cost of procuring all ingredients, equipment, delivery, processing, interest, depreciation and labor must be considered. The decision to process feed on the farm must not only be cost effective, but also requires that the owner be responsible for being knowledgeable about formulations and feed quality.

Feed processing on the farm can be done with varying amounts of complexity. Most simply, a PTO drive grinder mixer may be used to grind grains and mix with a purchased complete supplement, often called a ‘vitamin and mineral mix’, or ‘vitamin-mineral pre-mix’, which includes all other ingredients. As the size of the swine enterprise increases, justification for complexity increases, and a farmer may consider purchasing individual lots of a protein source, a calcium source, a phosphorus source, salt, a trace mineral premix, and a vitamin premix. In an older Pork Industry Handbook bulletin, Bloome and others[1] suggests 200 to 400 tons per year (30 to 60 sows farrow-to-finish) as the break-even volume of feed for a PTO grinder-mixer. The North Carolina State University Swine Nutrition Guide 7 suggests that 500 to 750 tons of feed per year justify use of a stationary mill and mixer for on-farm feed processing. It takes about 70 to 100 sows in farrow-to-finish production to justify raising corn, oats, or other grains and the costs of labor, transportation, feed manufacturing, and feed storage. Other questions to consider when deciding whether to process feed on-farm are presented in a Pork Information Gateway resource by Holden and Starkey[2].

Alternative Feedstuffs

Periodically, extensive producers have access to a surplus low-cost byproduct which they would like to feed to swine. These vary considerably in nutrient profile and availability based on location and season, making general guidelines for their use challenging. The challenges with feeding these alternative feedstuffs are: knowing nutrient availabilities and amino acid relationships in that alternative feedstuff. Thaler and Holden[3] have provided upper inclusion limits (amount or percentage) for various alternative feedstuffs. Farmers should seek the advice of a nutritionist, extension specialist, or consultant to evaluate ingredient and finished feed quality. When managed appropriately, there are many local sources of vegetables, dairy whey, root crops, and other alternative feeds that add variety to pigs’ diets and may reduce feed costs. Older swine husbandry books, some now available electronically, have nutritional values for some of these alternatives, but growers must recognize that there can be considerable variation around these averages.

Pasture and forage

Many extensive producers raise their herds on pasture or in woodlots, and the right kind of forages can add significant nutrients to swine feeding programs. For example, sows on good quality pasture can be fed less often and with a smaller amount of concentrate[4]. Forage adds protein, fiber, and essential vitamins and minerals to the diet, but should not be considered as a substitute for a grain-based complete diet. The nutritional value of forages depends upon the type and quality of plants in the pasture. As a rule of thumb, high quality forage can substitute for up to 20-30% of the diet. At the 20% mark, the farmer should consult with a nutritionist to make adjustments in formulation of the complete diet to ensure all nutritional requirements are being met. Opportunities for foraging grain or crop fields after harvest may be available seasonally. Silage may also be fed to sows [5], if protein and energy levels are maintained at appropriate levels in the overall diet.

Feed Co-op

In the history of swine production in North America, we can read about the formation of producer cooperatives. This is another historical approach which extensive swine farmers can consider. Like-minded extensive farmers can more easily experience the economies of scale by cooperatively buying complete feed or feed ingredients in larger quantities. Historically, this was referred to as a ‘feed co-op.’ If large enough, they could save substantial amounts of money by buying other supplies and equipment together as well. Of course the co-op needs to be managed and records maintained, so this benefit is not without some expense or effort.

Summary

Often mentioned in nutrition discussions is the fact that feed typically represents 60 to 75% of variable production costs in pig production. Extensive farmers looking to decrease feed costs must decide if the reduction in all costs with using a potential alternative does exist, and that they have the ability to control the quality of processing and presentation. The feed procurement approach should achieve desirable nutrition, health and productivity.

Additional information:

[1] Bloome, P., A. Jensen, L. Rottman, and E. Rothenberger. 1990. On Farm Feed Processing. Pork Industry Handbook, E-1064.

[2] Holden, P. and C. Starkey. 2012. Should I purchase or make my own feed? Pork Production How-To: Pork Information Gateway https://porkgateway.org/resource/should-i-purchase-or-make-my-own-feed/

[3] Thaler, B. and P. Holden. 2010. By-product feed ingredients for use in swine diets. Pork Information Gateway Factsheet PIG 07-06-01. Accessed at: https://porkgateway.org/resource/by-product-feed-ingredients-for-use-in-swine-diets/

[4] Kephart, K.B., G. R. Hollis, and D. M. Danielson, 2006. Forages for swine. Pork Information Gateway Factsheet 07-06-04. Accessed at: http://www.porkgateway.org/FileLibrary/PIGLibrary/Factsheets/07-06-04g_c052006.pdf

[5] Wheaton, H.N. and J. C. Rea, 1993. Forages for Swine. University of Missouri Factsheet G2360. Accessed at: http://extension.missouri.edu/p/G2360